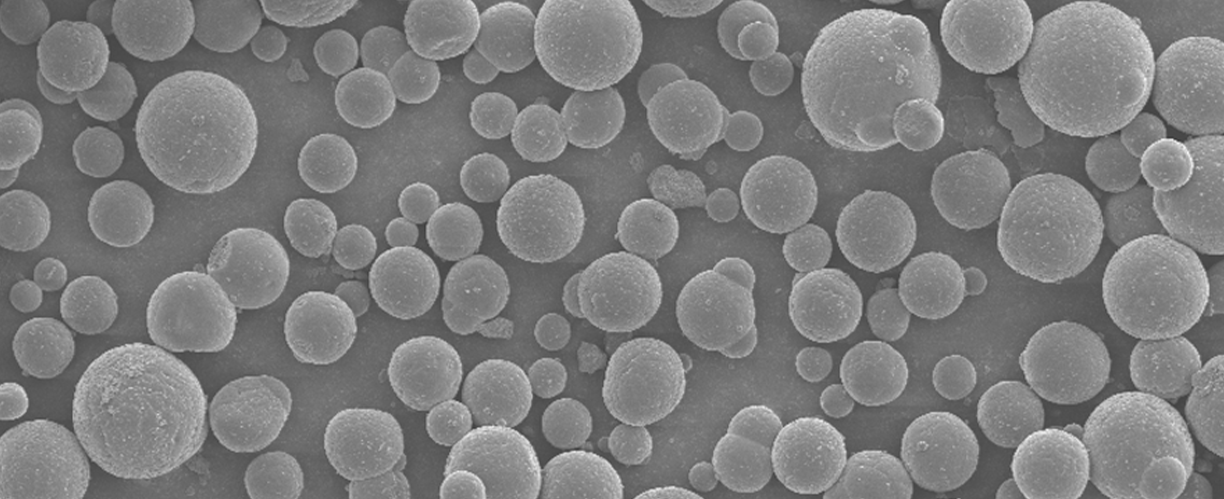

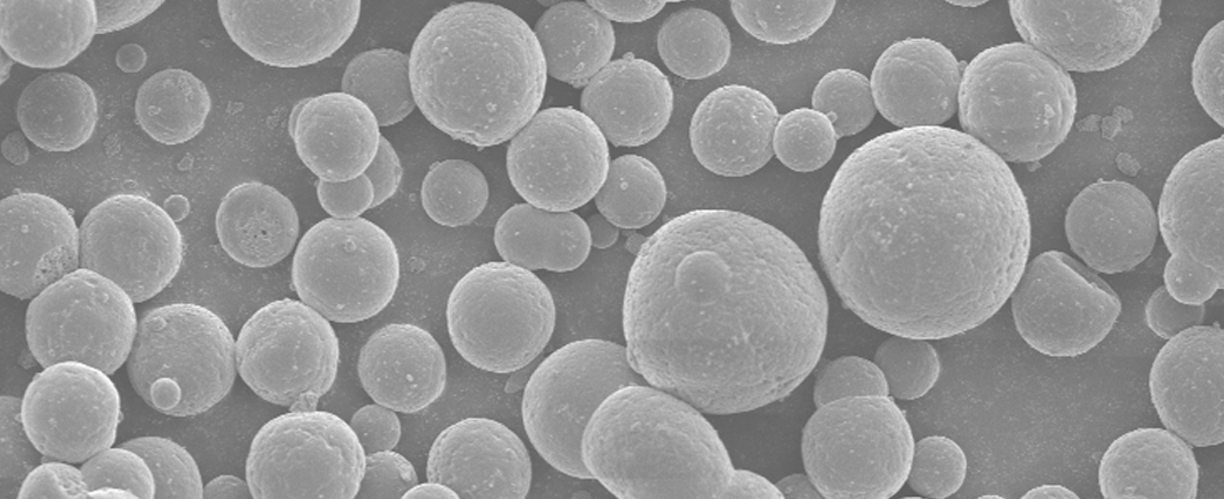

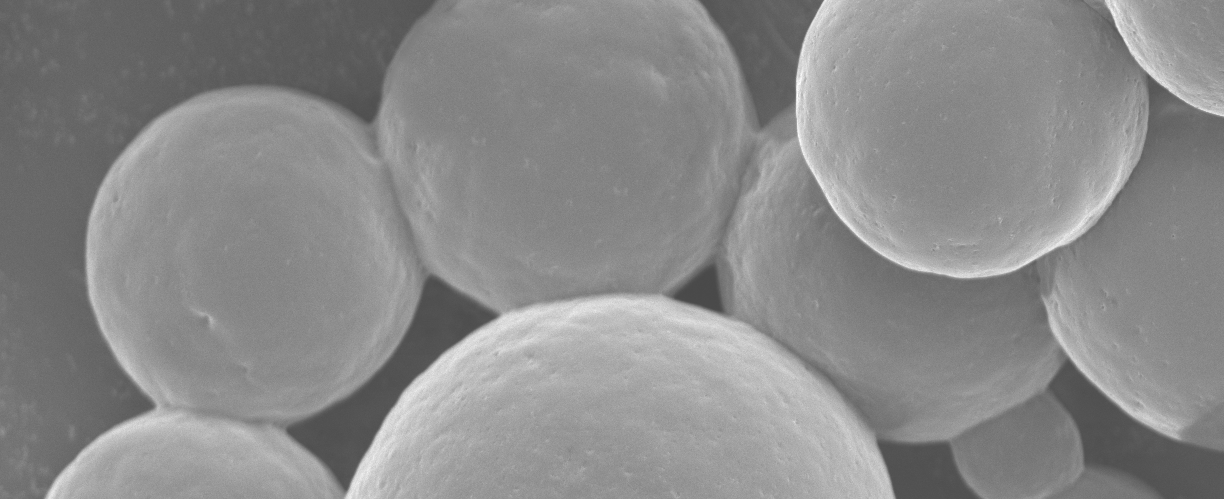

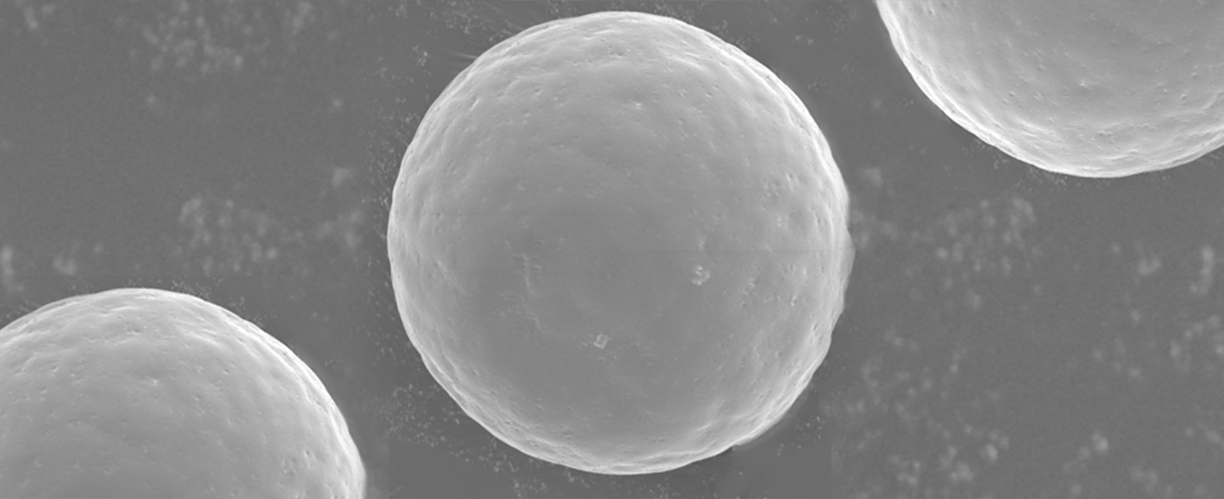

Microencapsulation technology is a technology that uses natural or synthetic polymer film-forming materials to encapsulate solids, liquids and even gases to form tiny capsules with a particle size of 1 to 5000 nm.

If the microcapsules are compared to dumplings, then the nutritional core material is like the "filling" of the dumplings, and the polymer material used to wrap the nutritional core material is the "skin" of the dumplings. A well-designed microcapsule can not only change the final form of the product, but also improve the efficacy of the product and broaden its potential applications.