-

With over 20 years of experience in human nutrition. We help you deliver better nutrition in your foods, beverages, or supplements.

With over 20 years of experience in human nutrition. We help you deliver better nutrition in your foods, beverages, or supplements. Check out our animal nutrition ingredients, designed to boost the health and vitality of all your favorite livestock.

Check out our animal nutrition ingredients, designed to boost the health and vitality of all your favorite livestock. -

We provide tailored health solutions across various fields with independent R&D technology.

We provide tailored health solutions across various fields with independent R&D technology. We offer professional teams to deliver customized solutions based on your product requirements.

We offer professional teams to deliver customized solutions based on your product requirements. -

Address common doubts and curiosities, offering clear and informative solutions. We demystify common queries and provide valuable insights in every issue!

Address common doubts and curiosities, offering clear and informative solutions. We demystify common queries and provide valuable insights in every issue! You can access comprehensive information to stay informed and ahead in your field. Explore and download our extensive library today!

You can access comprehensive information to stay informed and ahead in your field. Explore and download our extensive library today! -

INNOBIO announced its Corporate Social Responsibility (CSR) has received a Silver Medal Award from EcoVadis.

INNOBIO announced its Corporate Social Responsibility (CSR) has received a Silver Medal Award from EcoVadis. INNOBIO Europe B.V, the European branch of INNOBIO Co., Ltd. was launched in Rotterdam, Netherlands.

INNOBIO Europe B.V, the European branch of INNOBIO Co., Ltd. was launched in Rotterdam, Netherlands. -

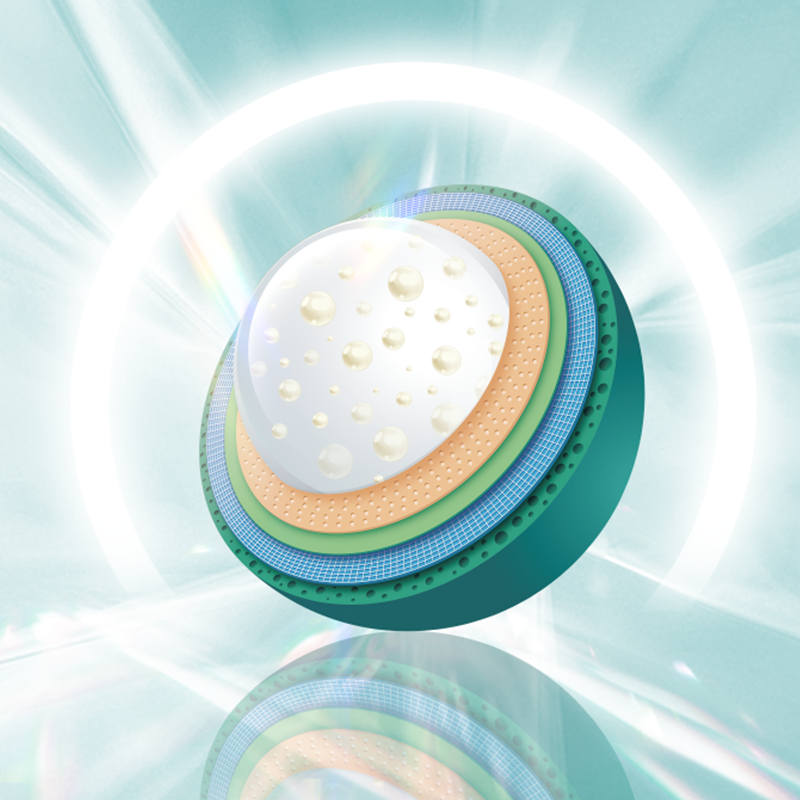

INNOBIO’s microencapsulation technology has evolved into its third generation (IMT 3.0) through iterative research of active ingredients, microencapsulating materials, equipment, and more.

INNOBIO’s microencapsulation technology has evolved into its third generation (IMT 3.0) through iterative research of active ingredients, microencapsulating materials, equipment, and more. With our patented biosynthesis technology platform, INNOBIO strives to provide an alternative to chemical synthesis to provide more natural and healthy ingredients to the nutrition industry.

With our patented biosynthesis technology platform, INNOBIO strives to provide an alternative to chemical synthesis to provide more natural and healthy ingredients to the nutrition industry.

- Home > About Us > Professional

Microencapsulation Technology

Nov 08,2024

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

INNOBIO’s Microencapsulation Technology (IMT)

INNOBIO’s microencapsulation technology has evolved into its third generation (IMT 3.0) through iterative research of active ingredients, microencapsulating materials, equipment, and more. We use a multidisciplinary approach to attack the challenge of stabilizing active ingredients with large molecular weights, optimizing delivery of active ingredients in the face of challenges such as limited absorption and the need for targeted or controlled release.

From IMT 1.0 to 3.0

IMT 1.0: Stable microencapsulation of active ingredients

When microencapsulation technology was first introduced into the field of food nutrition, INNOBIO’s R&D experts developed our 1.0 microencapsulation technology. This technology allowed us to completely wrap the active ingredient core material into an embedding material so that the core was completely protected from the external environment.

This not only improves the sensory properties of the active ingredient (appearance, smell, etc.), but also shelters it from the environment so that shelf life is greatly extended. Many ingredients that oxidized or harden as well as ingredients that have a strong smell were significantly improved after microencapsulation.

IMT 2.0: Diversified applications of active ingredients

With the continuous development of technology and market expansion, more specific requirements arose for microencapsulated products. Iterating upon IMT 1.0, INNOBIO made a leap forward in product dosage forms and applications.

Compared to IMT 1.0, IMT 2.0 expanded to various new dosage forms such as granules, emulsions, and solid beverages, allowing for a diversity in applications. Through a variety of technical improvements, our products had greatly improved mechanical properties, including instant solubility, taste masking, controlled release, and reduced absorption.

These advances in dosage forms allowed customers to safely add various nutrients to solid beverages, tablets, liquid beverages, nutritional gummies, baked goods, energy bars, yogurts, etc.

IMT 3.0: Efficient bioavailability of active ingredients

Today, the main research topic at INNOBIO is how to improve the bioavailability of microencapsulated ingredients to maximize the nutritional value of products. Building on the foundation of IMT 1.0 and 2.0, we further improve bioavailability by precise selection of embedding materials, strictly controlling the ratio of functional ingredients, and optimizing technical parameters of microencapsulation. At the same time, INNOBIO has significantly upgraded our manufacturing processes and equipment. Products produced with IMT 3.0 have passed CNAS inspection and certification and represent the culmination of our microencapsulation body of work.

PREVIOUS:

NEXT:

Related Information

Get product quotes for free, find the right solution with our experts.

Know more about our organization and teams, join us or meet at an exhibition.

Keep connecting with us. Say it and be sorted.

All Rights Reserved © 2024 INNOBIO Corporation Limited

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.